-

Mob.:

+86 135 9088 4785

+86 135 9088 4785

Item No:JK-FJD

Surface resistivity:106-108 Ω / cm2

Duration of validity:Two Years (The Surface resistivity will decay with the time)

Thickness:2.0、3.0、5.0.....20.0mm(Can be tailor base on customer requirement )

Sheet Size:2440*1220mm (Standard)

Anti Static acrylic Sheet is an acrylic sheet with a static dissipative coating that prevents electrical charges from being generated on the sheet surface. Having an electrostatic dissipative coating prevents electrical charges from being generated on the sheet surface. This allows Anti Static acrylic Sheet to control particle attraction and prevent electrostatic discharge (ESD) events completely independent of humidity. Achieve Anti Static acrylic Sheet controls static electricity for a variety of end uses. At the same time, Anti Static acrylic Sheet is simple to manufacture, light weight and can be used in large size sheets. Excellent optical properties, chemical resistance, surface hardness, and scratch/scratch resistance. It can control static electricity in many applications, including windows, doors, machine covers and enclosures, as well as manufactured dryers and cabinets.

DESCRIPTION

100% pure PMMA pellets

Anti-static Acrylic Sheet is kind of special surface treatment base on optical acrylic sheet to prevent the static, the base acrylic sheet is made from 100% pure PMMA pellets in the 10 thousands grade purification workshop. And the surface chemical treatment for anti-static is also in the dust-free environment and conforms to the environmental protection standard, already through SGS environmental protection authentication.

Features consistent surface resistivity

The Anti-static Acrylic Sheet features consistent surface resistivity of 109 to 1011 ohms/square, making them suitable for OEMs and processors who require best possible ESD protection and dust control. In case higher conductivity and lower surface resistance (107 to 108 ohms/square) are required.

Application

The Anti-static Acrylic Sheet widely used in Electrical & Electronic, optics, medical and clear production environment, such as clean rooms, medical equipment, battery cells, and electronic trays.

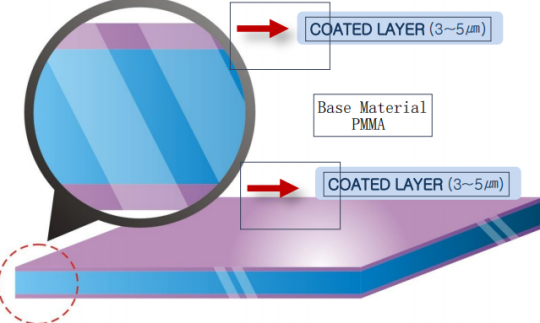

What’s the anti-glaring acrylic sheet

Do the surface chemical treatment base on optical acrylic sheet, which the chemical layer is kind of Conductive organic membrane, and the thickness is about 3-5 μm each side, this will make the acrylic sheet with anti-static function and meanwhile enhance the surface hardness,make it more anti-scratch

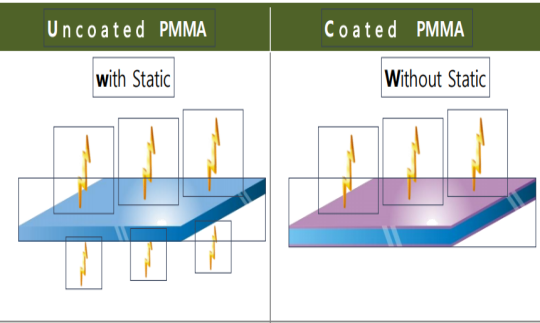

The Benefit of anti-static acrylic sheet

Normal acrylic sheet with electricity static and the electrostatic force act on the dust and then be transfer to the surface of the sheet, when contact with external conductor will have voltage discharge, this will cause the product quality problem for the semiconductor component;

While the acrylic sheet with special surface chemical treatment can effectively prevent the adsorption and accumulation of the dust, this will not cause quality problem caused from the static.

Anti Static acrylic Sheet is ideal for any applications involving electricity or electrically conductive surfaces including static control shields, glove boxes, conveyor line covers, electronic equipment and more. For more antistatic plastic sheets.

Anti-static

Lightweight

Excellent optical properties

Good chemical resistance

Good surface hardness

Copyright ©Kunxin New Material Technology Co., Ltd. All Rights Reserved | Sitemap | Technical Support: