-

Mob.:

+86 135 9088 4785

+86 135 9088 4785

Item: LGP

Material: PMMA or PS

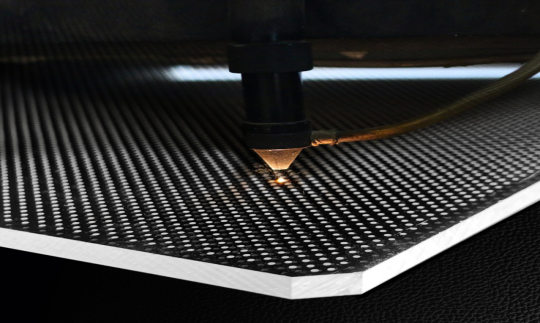

Process: Printing, Laser ethc, Molded Microlens, Extrusion...

Thickness: 2.0mm, 2.8mm, 3.0mm......

Size: Base on customer’s demands

Application:Led Panel Light, Light boxes,Emergency Lighting......

DESCRIPTION

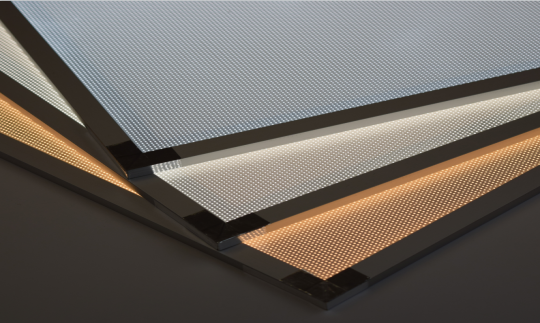

Different LGP Technology can be available

A Light Guide Plate is an acrylic or PS panel typically made from pure PMMA or PS resin. There are several ways to make these light guide plate, Printed Dot either white or black dots, laser etch or molded microlens or particulates are added into the panel itself. The purpose of all methods is to direct light out the front.

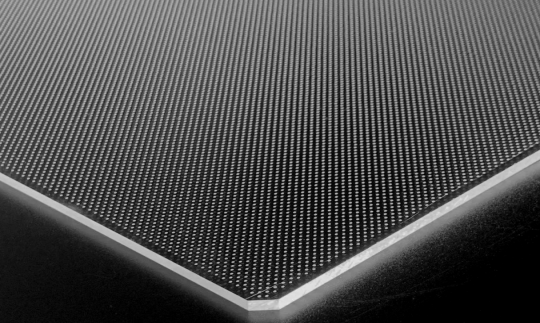

The highest uniformity and luminaire efficiency

Our Light Guide Plate is made from optical clear Mitsubishi acrylic or Optial Grating PS plate, a clear sheets of the highest quality, in which an optimized pattern is beamed or Screen Printed with the latest laser techniques, tailored to your dimensions. This innovative technology guarantees the Light Guide Plate with highest light output and a beautiful, fully evenly distributed appearance.The key is to have uniform light extraction from the bottom to top of Light Guide Plate ,so the patterns are less dense at the bottom and more dense at the top to eject the light to reach the highest uniformity and luminaire efficiency.

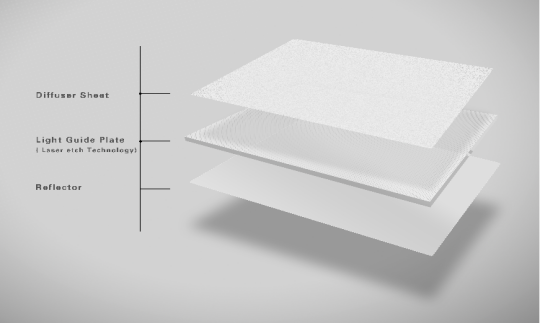

Light Guide Plate Components

Traditional the LGP plate are used for TV, commercial lighting fixture, indoor / outdoor lighting, smart home lighting, exit / emergency luminaires, medical lighting fixture / device and so on , and they are traditional edge-lit design structure, there would be 3 components.

Excellent Diffuser Sheet

A, Outer layer: Diffuser Provide light evenly and excellent scratch resistance

LGP Conduct Lights

B,Middle layer: Light guide plate conducts light evenly over the entire sheet

Reflector enhance illumination

C,Bottom layer : White Reflective film Prevent light leaking from the back and reflect all light source to the front

Our LGP Benefits:

1,Flexibility to serve customers with any special Requirement

2,Able to supply the complete optical plastic parts for manufacturers,such as the back Reflective film, the middle Diffuser Film and front Diffuser Sheet

3,Homogeneous light distributions across the panel.

4, Can make the doting design according to each panel size.

5,Can make various Size and Shape

6,Can meet your budge demands with different technology and material

New Application

Now LGP usage are trending to be more creativity, for example for some decoration products or craft application and more and more space can see the LGP appearing....

Copyright ©Kunxin New Material Technology Co., Ltd. All Rights Reserved | Sitemap | Technical Support: