-

Mob.:

+86 135 9088 4785

+86 135 9088 4785

The glass tube as the housing of the lamp continues the powder coating process of the traditional lamp. In order to eliminate the glare caused by high-brightness LED lamp beads on the human eye, LED lamp (hereinafter referred to as the lamp) housing design has a light diffusion effect (eliminate glare) whether using PC (polycarbonate) tube or glass tube. PC tube as the shell material of the lamp in the PC plastic processing process added silicone diffusion film, glass in the inner wall of the glass tube coated with light diffusion coating. LED light absorption loss also differs with the process used in the outer tube material or light diffusion material, which ultimately leads to different light transmission rate, light efficiency and beam angle.

PC tube can work in a wide range of temperatures (-60 ℃ to 120 ℃). Has the advantages of impact resistance, simple processing, easy to shape, no need to coat the light diffusion layer, no need to separately bond the lamp strip, not easy to damage during transportation and use, but the disadvantage is poor resistance to alkaline corrosion, easy to crack by force, long time light becomes yellow and brittle. The maintenance rate of the lamp is difficult to meet the requirements of more than 30,000 hours of LED lights.

The coating process of glass tube light diffusion coating is roughly the same as the coating process of traditional fluorescent lamps, but the raw materials used for coating powder have nothing in common. At present, the raw materials used for light diffusion coating can be divided into three types.

The first type is solvent-based coatings (also known as oil-based coatings), which is the most mature process developed in the coatings industry, and this coating has paint-like properties after drying and has the most reliable solidity. The most commonly used coating is a combination of solvent-based acrylic resin and silicone diffusion powder, which generally has a light transmission rate of up to 92%. Although the application process of solvent-based coatings is simple, they will be gradually eliminated due to the use of butyl or benzene diluents, which can produce great irritating odors and benzene pollution in production.

The second category is water-soluble paints. Water-soluble coatings use water as a thinner and water-soluble acrylic as a binder. The process is non-polluting. In the past two years, it has become an important research and development topic in the LED light industry and has achieved important results. Currently, all known adhesives of this type are cured to form a film by a cross-linking reaction that occurs after dehydration and drying. The biggest advantage is that the coating film after the cross-linking reaction is no longer soluble in water, and its firmness is second only to solvent-based coatings, but it is sufficient for the lamps. Although water-soluble coatings have many advantages.

The third one is evolved from the water coating process for fluorescent lamps, which uses light diffusers instead of phosphors for luminescence, and the binder is PEO (polyethylene oxide). For manufacturers of traditional fluorescent lamps, this technology is more mature, with high powder utilization, low production costs, good heat resistance of the coating, and good light transmission silica diffusion powder can reach 92%. Its disadvantage is that the solidity of the coating is slightly worse than the water-based paint, but because the adhesive PEO adhesive does not go through the baking process like fluorescent lamps, no high-temperature decomposition, its solidity is much higher than the powder layer of fluorescent lamps.

The process of wrapping a diffusion film around the outside of the glass tube has also made some progress. The technology for making light diffusion coating is to wrap a layer of PET (polyethylene terephthalate) film on the outside of the glass tube. This plastic film shrinks under certain high temperatures and wraps tightly around the outer surface of the glass tube. As the shrinkage film mixed with light diffusers, you can achieve the purpose of scattering light. This composite lamp combines some advantages of PC tube and glass tube. It has the advantages of high light transmittance, simple processing and good heat resistance. It can be used at 120℃ for a long time. Has strong toughness and tensile strength, not easy to break. Shows the superiority of high power lamp with length > 1500mm for easy processing. The disadvantage is the poor corrosion resistance of alkaline environment, not resistant to water immersion, easy to crack and fall off in the process of long-life light, the loss of light diffusion.

At present, the diffusion materials used in PC tubes and PET films are mainly silicone, while the light diffusion materials used in glass tube coatings are mainly silicone, calcium carbonate, talc, phosphor, yttrium oxide, silicon oxide, barium sulfate, etc. . The characteristics of these light diffusers are discussed extensively in this paper. This paper adds some properties and applications of silicone light diffusers.

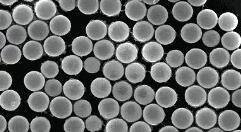

Among all the light diffusers, silicone light diffusers have the highest light transmission rate. The silicone transparent sphere material particles are added in micron size, and the micrographs are shown in Figure 1, which can be uniformly dispersed in the resin when used for PC, PET, and filler adhesive. The light from the lamp can pass through the transparent spheres in these film-forming coatings, so that the strong light from the LED lamp beads is refracted and reflected many times from the surface of the PC tube or PET film, turning the point light source into a surface light source, eliminating string light and softening the light. As the light passes directly through the light diffusion sphere, it avoids multiple reflections and absorptions and reduces light loss.

Silica gel particle microscope photos

Silicone light diffuser is easy to use in PC tube and PET film, but it needs special treatment in the process of water-soluble coating, otherwise it is difficult to disperse evenly to form a suspension, and the quality of coating is difficult to control. At the same time, it is also because it is transparent, in the case of high light transmission, the haze will be slightly reduced, so it is generally not used alone, mixed with inorganic light diffusers to better effect.

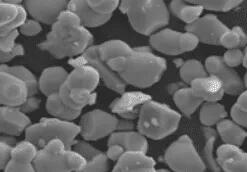

For inorganic light diffusers, light is reflected several times and then diffused evenly through the surface of tiny particles, but light is difficult to directly penetrate inorganic powder particles, inorganic light diffusion powder is also difficult to form spherical particles. Therefore, the light absorption of the diffusion powder itself increases, leading to a decrease in light transmission, while the light transmission of a good inorganic diffusion powder such as yttrium oxide can also reach about 91% (Figure 2). At present, by using good diffusion material coating and high quality PET film, the light transmission of LED T8 tubes can reach 92%. the light transmission of PC plastic tubes can also reach 91.5%, which has a lot to do with the absorption coefficient of plastic itself than glass. With the increase in light transmission, on the one hand, can improve the light efficiency of the lamps, on the other hand, can reduce the temperature of the lamp and extend the service life of the power supply components. It is because the light is difficult to directly through the powder particles of inorganic light diffusion powder, while increasing the number of reflections, the haze of the powder will also increase, so the haze of inorganic light diffusion powder is higher.

Fig. 2 Micrograph of yttrium oxide light diffuser

Table 1 shows the measured values of light transmittance for different weights (thicknesses) coated with solvent-based adhesive. From the table, it can be seen that the light absorption of the light diffusion panel increases with the increase of the coating amount, resulting in a gradual decrease of the light transmittance, and it is also found that when the powder coating (i.e., thickness) increases by 67%, the light transmittance decreases by only 1.7%.

| Powdered weight(g) | 3.9 | 4.5 | 6.5 |

| Light transmittance of powder tube(%) | 91.2 | 90.7 | 89.6 |

Table 1 Light transmittance of different powder layers

Measurements were performed on different sections of a 1.2 m long water-soluble glass tube coated with a water-soluble light diffusion layer. The powder tube was divided into zones every 300 mm, and then the light transmittance of each of the four sections was examined (see Table 2). From thin to thick, the transmittance decreased from 92.7% to 90.8%, a difference of 1.9%.

| Interval | 1 | 2 | 3 | 4 |

| Transmittance | 92.7 | 92.2 | 91.3 | 90.8 |

Table 2 The influence of different parts of powder tube on light transmission

By analyzing the transmittance of Na-Ca-Si glass tubes with different wall thicknesses, it was found that the transmittance of glass and powder tubes decreased slightly with the increase of glass tube thickness, but the degree of decrease was not obvious. The wall thickness increased from 0.65 mm to 0.90 mm, an increase of 38%, while the transmittance only decreased by 1.0% (see Table 3).

| Thickness of glass tube | 0.65 | 0.80 | 0.90 |

| Light transmittance of the same coating thickness | 90.5 | 90.3 | 89.5 |

| Transmittance of transparent glass tube | 98.0 | 98.0 | 97.6 |

Table 3 Effect of different thickness of glass tube on light transmittance

Lamp design depends on the parameters of the light source beam angle. LED T8 lamps always strive for a larger beam angle when replacing traditional T8 fluorescent lamps. Traditional T8 fluorescent lamps are non-directional lighting sources, and the lamps emit light at 180° cross section of C 0 ram, so when used for indoor lighting, the whole space has a feeling of transparency and gives a comfortable feeling. Visual enjoyment. LED T8 lamp, the light beads inside the light source strip are located at the top of the lamp and emit light at 180° toward the lamp. After the light is dispersed by different light diffusion paths, the directional beam angle formed in the C 0 ram 180° cross section is also different.

Large particle size of light diffusers can produce high haze, while small particle size can produce good light transmittance. Due to the limitations of the experimental conditions, the haze in the experiment could not be measured, and the haze could only be assessed by observing whether the lamp was transparent or not. Three inorganic coated lamps with average particle sizes of 1.1 μm, 4.6 μm and 8.0 μm were used to test the beam angles (see Table 4). From the experimental data, it can be seen that with the same lamp bead strip, the lamp bead is not visible at the end of the powder thickness. With the decrease of diffusion powder particle size and powder weight, the beam angle of the lamp gradually decreases, and the maximum difference of beam angle is found to be 50°.

| Particular Size of Light Diffusion agent( μm) | weight of powder | Beam angle° |

| 8.0 | 4.6 | 320 |

| 4.6 | 3.1 | 304 |

| 1.1 | 1.1 | 271 |

Table 4 effects of different particle sizes on beam

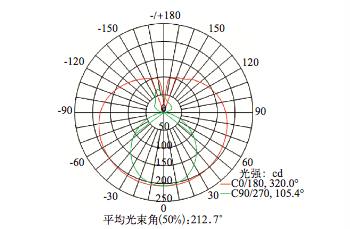

Using the same LED strip with different diffusion methods and materials, the beam angle is different. From the experimental results, the beam angle of PC tube, oil-based paint, PET film and water-based paint is basically the same, while the beam angle of light diffusion coating made by water coating process of traditional fluorescent lamps can reach about 320°.

| Material | oily paint. | water-based paint | PBT film | water-coated inorganic powder | PC tube |

| Beam angel ° | 209 | 220 | 214 | 320 | 205 |

Table 5 effect of different coating materials on beam angle

This is due to the larger particle gap of the traditional fluorescent lamp water coating diffusion powder coating compared with the above coating process (Figure 4). Inorganic light diffusion material powder particles for non-spherical, irregular polygon, particle size consistency is poor, coupled with inorganic light diffusion powder opaque, light can not directly through the powder particles, these lead to light must be reflected in the powder layer many times irregularly through the powder layer, light scattering after the emission angle is significantly greater than through the dense translucent uniform ball coating after the emission angle.

Fig. 4 Water-coated inorganic diffusion powder C 0/180 °beam angle 320 °

Light diffusion material plays a decisive role in the light transmission of the luminaire, of which silicone is the most ideal light diffusion material. The traditional PEO-inorganic light diffusion powder process has obvious advantages in increasing the beam angle of LED T8 lamps. Finding light diffusion materials with higher light transmission, better haze and higher cost performance for water-soluble light diffusion coatings is the focus of R&D for a long time to come.

Copyright ©Kunxin New Material Technology Co., Ltd. All Rights Reserved | Sitemap | Technical Support: