-

Mob.:

+86 135 9088 4785

+86 135 9088 4785

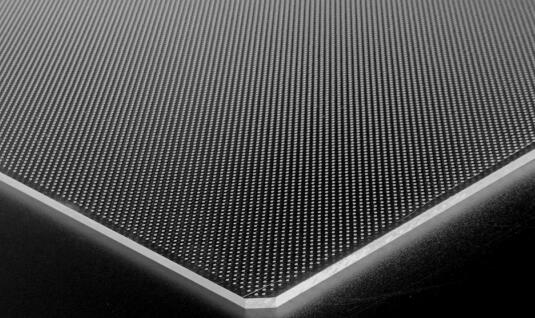

The production method of the engraved light guide plate and silk screen light guide plate is to print reflective dots or engrave grid lines on a transparent plate according to different sizes and areas, and use the ink dots printed on the surface of the light guide plate or the refraction of the engraved grid lines to make light Diffuse, realize the conversion of light source lighting into surface light source.

The production method of the nano light guide plate is to add nano-level light scattering particles while pouring acrylic. The nano particles can efficiently convert a point light source or a line light source into a uniform surface light source.

Advantages and disadvantages: Engraving light guide plates, silk-screen light guide plates must be based on the actual light box size to calculate the light guide point density, the production of this type of light guide plate requires special equipment and technology. Moreover, these two technologies are difficult to produce on a large scale according to the different needs of customers. Do not cut arbitrarily or bend hot. Must be equipped with astigmatism film, can not be used on both sides.

Application areas: lighting industry (flat panel lights), advertising industry (ultra-thin light boxes, crystal light boxes)

Light effect difference: the visual impact is relatively large at the point or line, the light and dark are distinct, and the surface is non-standard. The silk screen light guide plate is printed with ink dots, so there is light decay phenomenon.

Advantages and disadvantages: On the basis of the original board, it can be cut arbitrarily, hot-bent, without astigmatism film, and can be used on both sides.

Application areas: lighting industry (flat panel lights), advertising industry (ultra-thin light boxes). Different molds can be used to pour light guide elements of any shape, which is suitable for various industries as long as you have good ideas. But few people use nano light guides when making crystal light boxes, because their overall transparency is relatively poor.

Light effect difference: standard uniformity and softness.

Copyright ©Kunxin New Material Technology Co., Ltd. All Rights Reserved | Sitemap | Technical Support: