-

Mob.:

+86 135 9088 4785

+86 135 9088 4785

Item No: JK-TMB

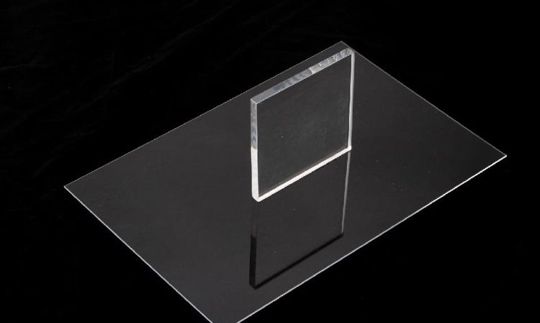

Color: Clear

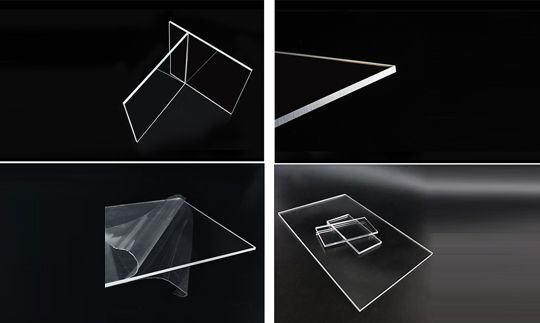

Appearance: polished Surface with PE film protected

Thickness: 0.4、0.5、0.6、0.8、1.0、1.2、1.5、2.0、3.0、5.0、10.0mm.... (Can be tailor base on customer requirement)

Sheet Size: 2440*1220mm (Normal)

1250*1680mm

The size can be customized

Application:Screen printing, LGP and various surface vacuum coating

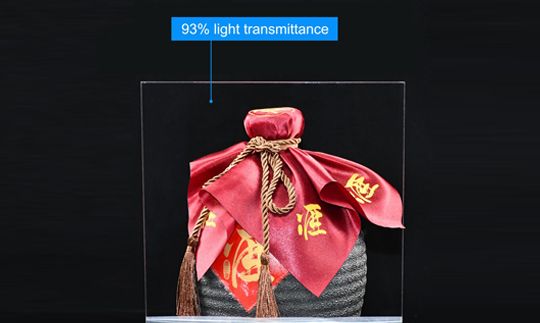

Perfect transparency and the light transmittance with 93%

Excellent electrical insulation, very light in weight

High plasticity, Processing and shaping easier

Strong surface hardness and good weather resisting property

DESCRIPTION

10 thousands grade purification workshop

Our optical Acrylic Sheet is kind of crystal transparent acrylic plate, which base on optical theory and advanced extruded technology, it is made from 100% pure PMMA resin from Mitsubishi through imported extruded equipment in the 10 thousands grade purification workshop .

Good quality for optical function

The PMMA sheet with even surface, smallest tolerance and glass feeling and conforms to the environmental protection standard, The optical quality is good guarantee of the idea base material for Screen printing, LGP and various surface vacuum coating to achieve the function such as Hard coating , Anti static, Anti Glare, Anti infrared ,Anti fog and so on.

Excellent Transparency

Transparent acrylic sheet is colorless and crystal clear, its transparency is the topmost one in all plastic, the transmittance is close to 93% for 100% virgin raw material from Mitsubishi Chemical

Good mechanical & thermal & Chemical processability

Very easy to carry out the secondary processing, such as heating processing, mechanical processing, vacuum shaping, screen printing and Vacuum coating and so on

Good weather resistance

Good adaptability to natural environment, long time under sunlight, wind and rain, its property will not change, Good aging resistance, it can be used safely outdoors.

Light, safe in use

Comparing with glass, its density is the half of glass, but the effects of use are just the same. Moreover, it will not scatter even if its break, so it is safe in use, because of this advantage, it is used widely as construction material to substitute glass.

Material characteristics

| Properties | Test method | Test condition | Result | |

| Density | ASTM D792-08 | 23±0.5℃ | 1.19g/cm3 | |

| Water absorption | ASTM D570-98 | 50±3℃,24h | 0.27% | |

| Light luminoustransmission | ASTM D1003-07 | Specimen thickness:3.0mm | 93.0% | |

| Haze | ASTM D1003-07 | Specimen thickness:3.0mm | <0.3% | |

| Heat distortion temp | ASTM D648-07 | Width:3.00mm,120℃/h Load:1.82MPa | 88.4℃ | |

| Vicat softeningtemperature | ASTM D1525-09 | Thickness:3.0mm,120℃/h Load:50N | 104.0℃ | |

| Mold shrinkage | ASTM D955-08 | 23±2℃,50±5%RH,48h | Parallel to flow | 0.37% |

| Mold shrinkage | ASTM D955-08 | 23±2℃,50±5%RH,48h | Perpendicular to flow | 0.31% |

| Tensile strength | ASTM D638-10 | Thickness:3.0mm,5mm/min | 61.8MPa | |

| Elongation at break | ASTM D638-10 | Thickness:3.0mm,5mm/min | 3.0% | |

| Tensile modulus | ASTM D638-10 | Thickness:3.0mm,5mm/min | 3270 MPa | |

| Flexural strength | ASTM D790-10 | 3.0mm,1.3mm/min48mm | 107 Mpa | |

| Flexural modulus | ASTM D790-10 | 3.0mm,1.3mm/min48mm | 3310 MPa | |

| IZODnotched lmpact strength | ASTM D256-10 | Width: 3.0mm1J | 15J/m | |

| (HRR)Rockwell hardness(HRR) | ASTM D785-08 | Width:6.0mm | 123 | |

| 20mm Vertical Burning Test | UL 94 | Specimen: 3.0mm | flammable | |

OUR PROJECTS

Copyright ©Kunxin New Material Technology Co., Ltd. All Rights Reserved | Sitemap | Technical Support: